Oil analysis of machinery is a well-established and competitive industry in the U.S. But grease, used as a lubricant in nine times as many of the world’s bearings than oil, is not. That’s because getting a reliable grease sample without shutting the machine down and tearing it apart is usually impossible, and subsequently it has become common practice for manufacturers to test only their oil-lubricated machinery.

Oil analysis of machinery is a well-established and competitive industry in the U.S. But grease, used as a lubricant in nine times as many of the world’s bearings than oil, is not. That’s because getting a reliable grease sample without shutting the machine down and tearing it apart is usually impossible, and subsequently it has become common practice for manufacturers to test only their oil-lubricated machinery.

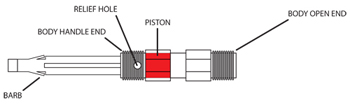

A small company in York has stolen the grease spotlight and hopes to sell its solutions to oil analysis labs across the country. Maintenance Reliability Group (MRG) in York has developed the Grease Thief, a grease sampling tool that allows for a consistent and representative sample to be taken.

“What we’re trying to drive home is if you test the grease prior to failure you can actually extend the bearings’ lives, save money and avoid costly downtime,” says MRG lab manager Lisa Williams.

Oil analysis labs have typically ignored grease analysis because available methods require oil. Grease, itself an oil that has been thickened to a specific grade, has its own grading system. MRG’s Grease Thief, initially made with a syringe pump bought on eBay, makes sure the grade is up to par. There are separate Grease Thief kits for electric motors, pillow block bearings and motor operated valves.

MRG is working with Airline Hydraulics in Bensalem on building an analyzer for the Grease Thief and plan to begin beta testing next month. MRG plans to sell the kits and analyzers to existing oil analysis labs to help these labs expand their business to include grease analysis. MRG’s biggest customer is the National Institutes of Health, for which MRG president Richard Wurzbach serves as a consultant as part of its Condition Based Maintenance Program. MRG has also helped a major pharmaceutical company, which was having bearings failures in its grease-lubricated machines at its headquarters, by doing a root cause analysis on the actual bearings.

MRG, which received about $75,000 from Ben Franklin Technology Partners last year, has recently entered into a partnership with the Millersville University Software Productization Center to develop software to manage the data gleaned from the Grease Thief and produce reports.

“The goal is to increase the productivity of the test,” says Williams. “We have a lot of data we need to know how to deal with.”

Source: Lisa Williams, Maintenance Reliability Group

Writer: Joe Petrucci