This story came to us via our reader survey about COVID-19 in Pennsylvania. Do you have something to share? Click here.

In Berks County, a grassroots effort is providing personal protective equipment (PPE) to workers who can’t stay home during the COVID-19 pandemic. The Berks PPE Resource Network is a consortium of folks at area colleges, school districts and public libraries, and home users like hobbyists and engineers working to 3D print face shields.

Everything started with a late-March brainstorm between local community groups, small businesses, higher-education institutions and manufacturers. According to Network organizer Ellen Albright, director of talent and workforce development at Greater Reading Chamber Alliance, the partners were wondering how to harness existing 3D-printing resources to produce PPE for front-line workers.

Turns out plenty of people were already at work.

“Instead of getting stuck in those questions — ‘How do we do that?’ or ‘What happens next?’ — we kept tapping this ad hoc committee that we had,” says Albright. “Take your piece of this and let’s run. Build the plane while you’re flying, because it’s not anything any of us had done before.”

It’s not only hospital workers who need the shields, though their PPE needs have understandably gotten the spotlight. According to Adelle Schade, a Network organizer and founder of the nonprofit Albright Science Research Institute, people like police officers, firefighters, Game Commission staffers, postal workers, grocery-store clerks, and even private-practice physicians have been going without face-shields while doing their essential jobs. The PPE Resource Network is fixing that.

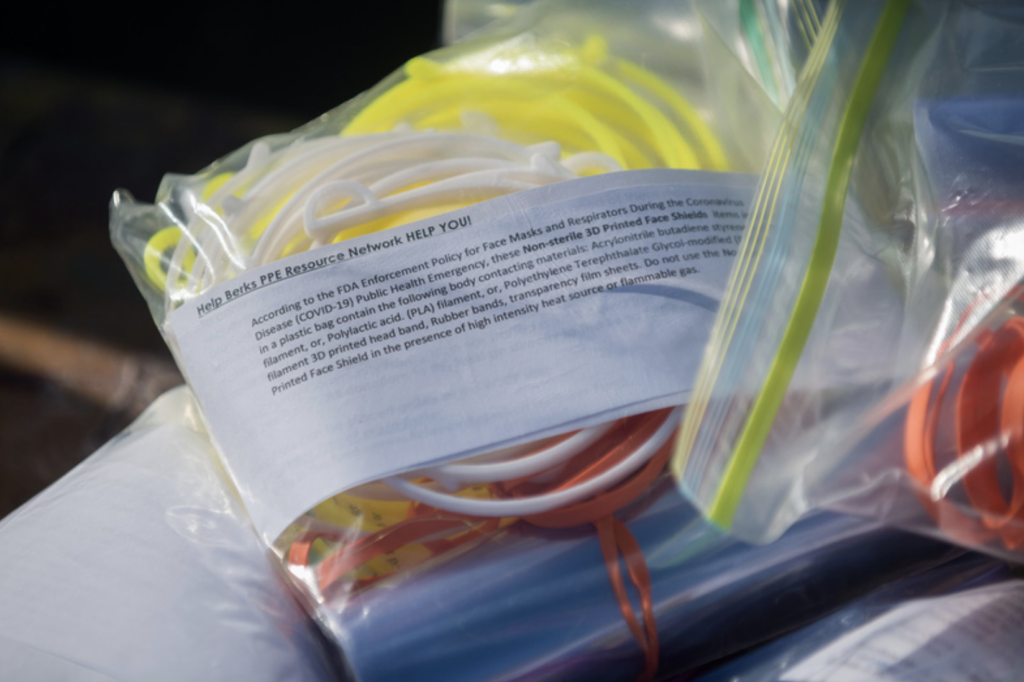

Their DIY shields have four components anyone can assemble: a wearable 3D-printed plastic band that wraps around the forehead, a rubber band that secures the plastic piece around the back of the head, silicone rubber bits that cushion the band as needed, and the plastic shield itself.

Take your piece of this and let’s run. Build the plane while you’re flying, because it’s not anything any of us had done before.Ellen Albright

Experiments led to three iterations of the 3D-printed band, says Kris Jackson, the cofounder of CrossTrainer Mixed Reality and co-manager of the VR lab at Reading’s GoggleWorks. Alongside printers donated from Penn State’s LaunchBox and Kutztown University, GoggleWorks is leading the printing effort (producing 15 bands at a time, every 10 hours or so).

Network leaders estimate that about 70 people are now volunteering for the effort, 50 of those printing bands. One family of three works continuously in three shifts to keep the homeprinting going 24 hours a day.

And what about the shields themselves?

“We raided a bunch of schools for transparency sheets, give it a three-hole punch, and this locks right into the print,” explains Jackson, demonstrating how the plastic sheet snaps into the newly printed plastic band to create a wearable face-shield.

The team is already tackling a looming shortage of shields as school supplies give out. They’re teaming up with three organizations that will help mass-produce plastic shields. American Polarizers is donating industrial plastic rolls, and Reading Area Community College will put its Schmidt Center (dedicated to manufacturing education) to work cutting and punching holes in the shields. Sabold Design is also stepping up with plastic rolls, cutting, and punching — and they’re all doing it for free.

Filament supplies (the plastic that feeds into the printers) are running a little low, but between donated stocks from printer providers and the GoggleWorks stockpile, participants can get what they need. The Network hopes to purchase more thanks to funding via the Berks County Community Foundation, including donations from Berks Alliance, the Friends of Reading Hospital, and individual givers.

Wednesdays are distribution days. GoggleWorks is the headquarters. Early in the morning, band-makers, gloved and masked, register their arrival in advance and drop off their stock. Team members sort bags of masks (15 each) with all their parts and assembly instructions; they’re ready for pick-up in the same place an hour later.

“We’re going to do that every Wednesday in the GoggleWorks parking lot until we’re not needed anymore,” says Schade.

What began as something for Berks County has grown into more of regional effort. And others are taking notice.

“There’s a lot of counties in the state and in this country who are just like Berks County and don’t have the things they need,” she explains. Schade hopes growing awareness of the effort, including its new website, will help others mobilize (visit to submit a request for shields or to get involved).

The Berks PPE Resource Network is a “Band-aid,” leaders say. Soon, they hope, businesses will have the capacity to produce and sell needed gear. But until then, volunteers are busy around the clock to protect workers from COVID-19 infection. Whether it’s community-wide organizations or individuals at home, participants “don’t know where the stuff is going or who it will impact,” says Albright, “but they know it’s what [people] need right now.”

She hopes the initiative behind the project is just getting started.

“This is a crisis and we’re addressing a need,” she says. She hopes to leverage this county-wide skill and engagement in the future. “Things are going to look a lot different after this settles down, whether we want them to or not.”

ALAINA JOHNS is a Philadelphia-based freelance writer and the Editor-in-Chief of BroadStreetReview.com, Philly’s hub for arts, culture and commentary. You can visit her at her blog, where fiction need not apply.

Photo Credit: Berks County Community Foundation