Pittsburgh is about to gain only the fourth robotics and hardware startup accelerator in the world, thanks to quicker and more easily available prototyping equipment, local manufacturing, readily accessible crowd funding and, most crucially, the resources and experience of AlphaLab, the software startup accelerator that was itself a pioneer when it opened in the city's South Side in 2008.

AlphaLab was founded by Innovation Works, the Ben Franklin Technology Partner of Southwestern Pennsylvania, which is supported by the state's Department of Community and Economic Development. Twice a year for five months each, AlphaLab provides six companies with a $25,000 investment, an office, business planning, mentoring and educational events to help them grow and launch their companies. Each company then gets a chance to demonstrate its product to national press and potential backers, including Innovation Works' committed seed-stage investors.

“We saw many of the same dynamics that made accelerators work for software companies happening in the hardware space,” says AlphaLab Executive Director Jim Jen. “After some successful pilots, we decided to launch AlphaLab Gear to capitalize on Pittsburgh’s strengths in this area and to be on the front end of a large, global movement.”

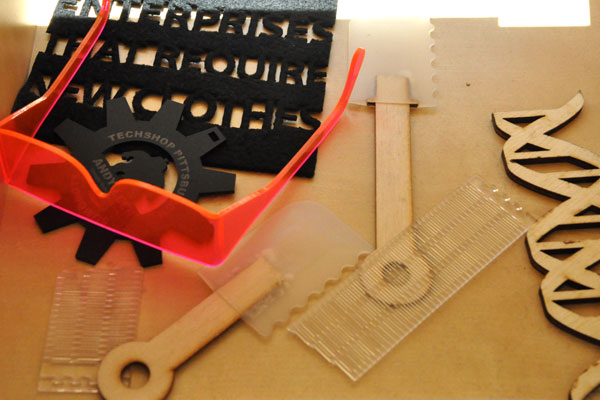

AlphaLab's new division for robotics and other hardware, AlphaLab Gear, is negotiating a lease for its own 10,000-square-foot space, but will be run along the AlphaLab model. AlphaLab took in its first hardware company a year ago, then three in its last session, finding that they could indeed help such companies become investment-ready. Hardware companies need lengthier AlphaLab involvement, so Gear will give them eight months of resources, and they also require access to more equipment, so AlphaLab Gear is partnering with TechShop, which opened in March, offering publicly available high-tech equipment to members. Gear startups will have a free membership in TechShop and will have light fabrication capabilities available in the Gear space itself.

“What we're hoping to happen is similar to many of the things that happened with AlphaLab,” says Jen. “We want to leverage the network we've built and the methodologies but let AlphaLab Gear focus on the unique capabilities of hardware companies.”

“Today you can come up quickly with a prototype and test it,” thanks to such innovations as 3D printing and open-source software, says Ilana Diamond, Gear's Managing Director. “And Kickstarter has served as a proxy for investors seeking customer validation,” she adds, referring to the popular crowd-funding site.

Still, she cautions, “There are a lot of moving pieces in hardware companies.” They require teams whose members possess engineering skills and the talent for sourcing components, undertaking concept testing and user testing, designing for manufacturing and figuring out distribution and inventory management systems, among other capabilities.

” Something that differentiates us from any other way to get your company off the ground is our high caliber pool of mentors,” Diamond says. AlphaLab Gear will assign three or four mentors to each fledgling company accepted into the program. “These folks roll up their sleeves and get involved,” she says. “We identified mentors who have launched hardware companies and been successful entrepreneurs themselves and who can help in all areas” that hardware companies will require, she adds. Thus, AlphaLab Gear participants “will have somebody to say, 'Try this,' or 'Call this person.' Our goal is, when they leave our program, they are fundable … and operating right here in Pittsburgh.”

A Collaboration Station

AlphaLab is teaming with the investment firm StartBot, run by founder and Managing Director Josh McElhattan, to create a funding stream for these early-stage robotics companies, which can choose to receive a smaller or larger investment in exchange for 5 percent or 9 percent equity.

“This is one way for us to help robotics technology to become more business-ready in Pittsburgh,” he says.

At Industrial Scientific Corporation in Pittsburgh's Oakland neighborhood, McElhattan reports, he had great success bringing back a lot of manufacturing from China, “at like cost and higher quality, and that's a story that has been repeated at a lot of American manufacturing companies.

“The hardware startup is really a movement that is gaining a lot of traction – the idea that starting a hardware company is just as easy as starting a software company,” he adds.

McElhattan recalls working on a website startup 15 years ago, when it took 30 people one year to ramp up. Now he can do a website himself over a weekend. “That speed to market is happening now with hardware companies,” he says.

AlphaLab Gear applications have already arrived from as far away as Singapore and South Africa, as well as New York and Pittsburgh, for companies proposing to make wearable sensors, 3D printers, smartphone add-ons and tools for clothing manufacture. The early application deadline is July 15 for a response by August 15; final deadline is Sept. 3.

“We don't specify the type of company or even a specific stage of company for the applicants,” says Diamond. It could be a team still at the idea stage or one close to production but still trying to scale up and redesign for mass manufacturing. The most important selection criterion: ” Do they have a product that solves a problem that’s important enough for people to open their wallets and pay to solve that problem.

“And it has to be something that will be capital-efficient” – that is, worth investing in, she explains. “It has to be a passionate team that has the capabilities to do what they say they are going to do.

“We want to take the best companies that apply,” she adds. “If they're all robotics, fine, but that isn't our goal.”

“We don't have a narrow definition of what hardware or even robotics means,” says McElhattan. “We're keeping it wide on purpose. Over the years, we may develop some specialty zones. We're at the beginning of a long period of growth in hardware accelerators. There will probably be four more in the following year, and then 40 more. I feel like we're just on the map.”

Time to Make

“It's timely that TechShop opened here at the beginning of March,” says Les Gies, its senior accounts manager. TechShop bills itself as “America's first nationwide open-access public workshop”; Gies says it's for “creative types: makers, hobbyists and businesses.”

TechShop Pittsburgh has more than $1.5 million worth of equipment and software available for use by members at $125 a month ($95 for students). “We're basically democratizing the tools of innovation,” Gies says. “TechShop is making the physical product possible and AlphaLab Gear is making the steps toward that possible.”

In fact, a current AlphaLab company, SolePower, has been in TechShop since it opened. “They have a sole insert for your shoe that is actually capturing and storing your kinetic energy,” allowing you to charge your small electronics as you walk, he explains. “They're seeing how hardware and software are coming together into agile hardware. You see a lot of this happening with wearable technology – hardware with the software intelligence built into it.”

Pittsburgh is a great place for AlphaLab Gear, Gies says. “We're a manufacturing town, a place where things have been built in the past” – and Pittsburgh still has a manufacturing base. “We have the intellectual base of CMU, Pitt and other universities. All of that has been here for many, many years.”

“The fact that TechShop chose Pittsburgh as one of its early locations is a vote of confidence that Pittsburgh is going to be a hub for this type of manufacturing,” says McElhattan. “We think that that movement and the infrastructure and workforce of Pittsburgh are a perfect match.”

Diamond agrees. She has already heard from officials in another U.S. city who are planning a visit as they consider a hardware accelerator of their own. “AlphaLab was one of the first accelerators in the country. Now there are hundreds of them,” she says. “We believe the same will happen here too. But we have an advantage. We're from Pittsburgh. We make stuff. We have the manufacturing capability. We have the history. It's in our DNA.”

MARTY LEVINE is the editor of sister publication Pop City's For Good section. Send feedback here.