In the face of competition from overseas, the demise of family-owned dental laboratories and a struggling downtown, DeLux Dental Laboratory Inc. is growing and thriving in the heart of Reading.

Thanks to the fact more people are financially comfortable enough to pursue the perfect smile, there’s a huge demand for dental care services. Dental surgeries like Burwood Dental Care offer braces, veneers, clear aligners, and Invisalign as more people look for the different services that will be able to improve their smile. However, it’s not just dental surgeries that are seeing this demand, the manufacturers and laboratories that serve the dental industry are seeing huge demand.

This is where companies like DeLux Dental come in. Founded 65 years ago by Richard Held and two partners, DeLuxis now co-owned by Held’s son, Douglas Held (president and consultant) and Joseph Bakanowski (vice president and treasurer). Both are certified dental lab technicians who worked at DeLux starting in the 1970s.

Originally located at 824 Walnut Street in a modest building near Reading’s City Hall, DeLux employed 12 people for many years, supplying Berks County dentists with dental prosthetics (crowns, bridges and dentures).

But as the 21st century began, they found themselves struggling against trends in the industry. Thanks to high labor costs, labs began sending specifications for crowns and dentures overseas to be fabricated. At the same time, dental technology schools began closing down. Small labs, unable to compete, also began to close.

According to Gary Iocco, president of the National Association of Dental Laboratories and Dimension Dental Design in Hastings, Minn., the country has lost 3,000 dental labs. Three large conglomerations — the Dental Services Group, National Dentex and MicroDental Laboratories — are buying up labs as owners retire or give up their businesses.

With the writing on the wall, the owners of DeLux Dental Laboratories knew they had to make some drastic changes if they wanted to stay open. By making small yet effective changes, like making sure that all of their chemicals were stored using these xylene resistant labels, to increasing their other health and safety measures, this wasn’t going to be easy. The first job on their list required them to grow in order to stay competitive.

“At first we looked at some of the corporate centers (outside the city), and found out how pricey they were, and how big,” says Deborah Bakanowski, Joseph’s wife and administrator/special projects coordinator at DeLux. “Then we looked at this building [832 Walnut Street]…It was the right size building, the right location, and we have the police department right here.”

At that time the city had a lot of properties available, and wanted to unload them. The building was dilapidated, with water coming in every time it rained. DeLux bought and rehabilitated the space — it now has a cozy conference room with a gas fireplace, a kitchen/employee lounge, offices on the first floor and a lab upstairs.

They also bought the buildings between 824 and 832 for possible expansion, put two apartments into 824 (which may be rented to employees), and bought a small parking lot down the street.

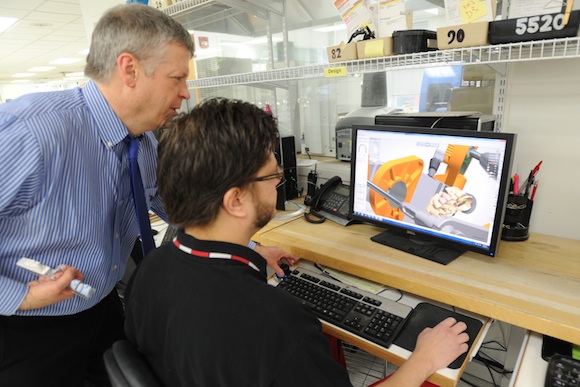

At the same time, the owners invested in CAD/CAM technology, a state-of-the-art milling machine, and other sophisticated equipment; they will soon be adding a 3-D printer.

As Joseph and Held gave a tour of the lab, their pride and excitement was palpable.

“In the digital world, we can meet with clients [dentists] at a distance,” says Joseph. “We can see the proposed restoration on the computer screen…and we can show our design to the dentist so he can see exactly what it looks like and make suggestions.”

Even the current process of having the dentist take a physical impression of the patient’s mouth may become a thing of the past. Two DeLux clients are already experimenting with taking digital impressions using a wand, and sending the specs directly via e-mail.

In addition to making traditional crowns with porcelain fused to metal alloys, DeLux is using the more up-to-date zirconium oxide for all-ceramic restorations. (According to Iocco, outsourcing, which accounted for 38 percent of dental prosthetics until recently, is slightly down, to 34 percent, partly because of bad publicity about lead in foreign-made crowns.)

While the new technology can automate some of the intricate steps involved in making dental prosthetics, there is still important work to be done by hand, including matching the color of the crown to the natural teeth.

“A machine can’t do that,” explains Joseph. “It takes a good eye.”

Some of DeLux’s employees are actually ex-art majors with degrees from Kutztown University. According to Deborah, they’ve found this service-oriented work to be rewarding and well-matched for their visual and practical skills. DeLux trains its employees, most of whom are college-educated. Some are studying to be certified technicians; all are highly skilled in the various aspects of the business.

“Nobody had to be let go because of the new technology,” she says. “They embraced it and asked to learn how to work with it.”

Held, who specializes in dental implants, explains that when they brought the digital equipment into the lab in 2010, he went to Salt Lake City, Utah, to be trained in CAD. When they purchased the milling machine, he learned CAM.

He details (via PowerPoint presentation) the unbelievably complicated process of placing a full set of implants, from meeting with the client to the finished mouth.

“It can be a life-changing service,” says Held. “It’s restoring a person’s smile and ability to chew.”

For this reason, DeLux belongs to Donated Dental Services, helping low-income people and cancer patients receive dental care. The company provides free appliances, mostly dentures, through this organization.

These days, DeLux has 35 employees, including Joseph and Deborah’s daughter, a technician. It is one of 200 labs in the country certified by the National Board for Certification in Dental Laboratory Technology, which guarantees safety and good management practices. The company has about 225 clients in Berks County and as far away as Pottsville, Allentown, Lancaster, West Chester and Collegeville, and even a few outside the state.

Iocco says that what DeLux did is exactly what dental labs must do to survive in the global economy.

“We can’t compete on labor rates,” he says. “But, with CAD/CAM and digital technology, we can compete. We have to change our business model.”

He is also impressed with DeLux’s commitment to Reading’s downtown and with their growth.

DeLux prides itself on “making everything right here,” says Deborah.